Introduction

Backhoe Attachments are the unsung heroes of backhoes, enhancing their functionality and versatility, and allowing operators to tackle a wide array of tasks with ease. Whether you’re digging, lifting, or demolishing, having the right attachments can significantly improve efficiency and productivity. In this article, we’ll explore the top five attachments every backhoe operator needs to unleash the full potential of their machine

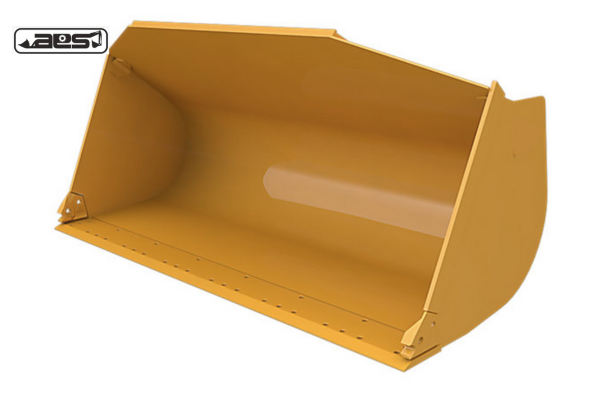

Bucket Attachments

General Purpose Bucket

In Backhoe Attachments It could be a physical bucket designed for a wide range of tasks, or in a more abstract sense, it might represent a flexible and adaptable resource or tool that can be applied to different situations. The term could also be used in a metaphorical sense to describe a versatile solution or strategy that serves multiple needs. If you have a specific context or use case in mind, feel free to provide more details for a more tailored response.

Trenching Bucket

A trenching bucket is a specialized Backhoe Attachments for heavy machinery, such as excavators or backhoes, designed specifically for digging trenches. These buckets are characterized by their unique shape and features, which allow them to efficiently and precisely excavate narrow and deep channels in the ground. Trenching buckets typically have a longer and narrower design compared to general-purpose buckets, enabling them to create trenches of various depths and widths for applications like laying pipes, cables, or other underground utilities. The specific design of a trenching bucket may vary based on the intended use and the type of soil or material being excavated.

Grading Bucket

The Backhoe Attachments grading bucket is a specialized Backhoe attachment used with heavy machinery, such as excavators or backhoes, for the purpose of grading or leveling surfaces. Unlike standard buckets, grading buckets are designed with a flatter profile and sometimes feature a cutting edge along the bottom. This design allows for smoother and more precise grading operations.

Grading buckets are commonly employed in construction and landscaping projects where achieving a level or graded surface is crucial. They are effective for tasks such as preparing building sites, creating foundations, or shaping terrain for roads and landscaping.

The flattened shape of a grading bucket enables it to skim across the surface, removing excess material and distributing it evenly to achieve the desired grade. These buckets come in various sizes to accommodate different machinery and project requirements.

Auger Attachment

Overview of Auger Attachment

An auger Backhoe Attachments is a tool designed to be mounted onto heavy machinery, such as skid-steer loaders, excavators, or tractors, to perform drilling or hole-digging tasks. The primary purpose of an auger attachment is to bore holes into the ground for various applications, ranging from construction and landscaping to agriculture.

Key components of an auger attachment typically include:

- Auger Bit: The spiral-shaped metal drill that rotates to dig into the ground. Auger bits come in various sizes to accommodate different hole diameters.

- Drive System: The mechanism that powers the rotation of the auger bit. Depending on the attachment and the machinery it’s mounted on, the drive system can be hydraulic, mechanical, or powered by another source.

- Mounting Bracket: The part of the attachment that connects to the machinery. It provides stability and support for the auger during operation.

Auger Backhoe Attachments are versatile tools suitable for a range of applications, including:

- Foundation Digging: Used in construction for drilling holes for foundations, footings, and piers.

- Fence and Post Installation: Ideal for creating holes for fence posts, signposts, or other vertical supports.

- Tree and Shrub Planting: Helpful in landscaping for digging holes for planting trees, shrubs, or other vegetation.

- Excavation and Soil Sampling: Used in various industries for drilling into the ground to collect soil samples or for specific excavation needs.

The adaptability of auger attachments makes them valuable tools in numerous industries, offering an efficient and precise means of creating holes in the ground for different purposes.

Applications and Benefits

Auger Backhoe Attachments excel not just in speed and efficiency but also in remarkable versatility. Their capacity to bore holes of diverse diameters and depths renders them indispensable across a spectrum of applications, spanning construction, landscaping, and agriculture. These attachments prove essential for tasks demanding precision and adaptability, offering a swift and efficient means of drilling. Whether it’s creating foundations, planting trees, or installing utilities, auger attachments stand as versatile tools, meeting the varied needs of construction sites, agricultural fields, and landscaping projects with proficiency and effectiveness.

Hydraulic Hammer

Breaking Down Materials

When faced with stubborn materials such as concrete, rock, or asphalt, a hydraulic hammer is the tool of choice for breaking them down quickly and efficiently. By delivering powerful percussive blows, hydraulic hammers can demolish even the toughest surfaces with ease.

Versatility of Hydraulic Hammer

In the Backhoe Attachments a hydraulic hammer, also known as a rock breaker or hydraulic breaker, is a versatile tool commonly used in construction, demolition, and mining industries. Its primary function is to break or demolish hard materials such as rock, concrete, and pavement. The versatility of a hydraulic hammer stems from its ability to perform a variety of tasks efficiently. Here are some key aspects of its versatility:

- Demolition: Hydraulic hammers are extensively used in demolition projects to break down structures, concrete walls, and reinforced concrete. They provide a powerful and precise means of breaking apart materials.

- Rock Excavation: In mining and quarrying operations, hydraulic hammers are employed to break and excavate hard rock. This is particularly useful in activities like tunnelling or extracting minerals.

- Concrete Breaking: Whether it’s removing old concrete structures, breaking up foundations, or dismantling pavement, hydraulic hammers are effective tools for breaking concrete into manageable pieces.

- Trenching: Hydraulic hammers can be used for trenching applications, breaking up hard soil and rocks to create trenches for various purposes, such as laying utilities or pipelines.

- Pile Driving: Some hydraulic hammers can be adapted for pile driving, making them useful in construction projects that involve driving piles into the ground to provide structural support.

- Road Construction: Hydraulic hammers play a role in road construction by breaking and removing existing pavement or rocks, preparing the ground for new road surfaces.

- Landscaping: In landscaping projects, hydraulic hammers can be utilized for tasks like breaking up large rocks, shaping terrain, or preparing the ground for planting.

The versatility of hydraulic hammers is attributed to their adaptability to different carriers, such as excavators, backhoes, or skid-steer loaders. Their ability to deliver powerful, controlled impacts makes them indispensable tools in various heavy-duty applications across multiple industries.

.

Grapple Attachment

A tiltrotator is a specialized hydraulic Backhoe Attachments used in conjunction with excavators or backhoes to enhance their capabilities and increase efficiency in various construction and excavation tasks. This attachment consists of a rotatable platform that can rotate (similar to a wrist motion) and tilt (similar to nodding or tilting the head). It is installed between the arm and the bucket of the excavator, providing additional degrees of freedom for more precise and versatile operations

Handling Debris and Materials

Whether it’s clearing brush, loading logs, or moving bulky materials, a grapple Backhoe Attachments is indispensable for handling a wide range of debris and materials. With its rugged construction and powerful grip, a grapple attachment can make short work of even the most challenging tasks.

Different Types of Grapple Attachments

From single-arm grapples for light-duty tasks to clamshell grapples for heavy-duty material handling, there are various types of grapple attachments available to suit different applications. Choosing the right grapple for your specific needs can significantly enhance productivity and efficiency.

Tiltrotator

Enhanced Maneuverability

For unparalleled precision and control, in Backhoe Attachments the tiltrotator attachment stands unrivaled. This cutting-edge device empowers operators to execute hydraulic precision in rotating and tilting attachments, providing effortless access to confined spaces and angles. The innovative design enhances maneuverability, allowing operators to navigate tight spaces with ease. The tiltrotator’s hydraulic capabilities ensure exact control, making it an indispensable tool for achieving precision in various tasks. This attachment redefines the standards for control and adaptability, enabling operators to accomplish intricate maneuvers and tackle challenging environments with unmatched efficiency.

Increased Efficiency in Various Tasks

Whether it’s grading, landscaping, or digging, a tiltrotator attachment can significantly improve efficiency and productivity by eliminating the need for manual repositioning and adjusting. With its ability to rotate 360 degrees and tilt up to 45 degrees in any direction, a tiltrotator attachment unlocks a whole new level of versatility and performance for backhoe operators.

Conclusion

In conclusion, selecting the appropriate Backhoe Attachments for your backhoe is pivotal in unlocking its full potential. The right attachments, including buckets, augers, hydraulic hammers, and grapples, empower your backhoe to execute a diverse range of tasks with precision and efficiency. Investing in high-quality attachments is essential for maximizing productivity, ensuring that your backhoe is equipped to handle various challenges effectively and deliver optimal results. From excavation to material handling, the strategic choice of attachments transforms your backhoe into a versatile and powerful tool, guaranteeing success in a wide array of projects.

FAQs

What is a backhoe attachment ?

As an alternative to using a self-contained backhoe loader machine, a backhoe attachments gives you access to many of the same functions. These work tools connect to another piece of compact earthmoving equipment — typically a skid steer loader — via quick couplers.

Are backhoe attachments worth it ?

Backhoe attachments is an efficient tool for performing various heavy lifting and excavation tasks. Backhoes attached to your tractor PTO are a widely used modality, and that says a lot about its worth as a tool.

Why backhoe attachments used ?

They can tackle both flat surfaces and inclines. Backhoes are versatile. They come with a bucket and digging arm that can perform many different tasks, such as digging, small demolitions, moving materials, landscaping, breaking asphalt, and paving roads. Attachments can expand the range of what they can do

What safety precautions should be taken when using backhoe attachments?

- Always read and follow the manufacturer’s instructions.

- Wear appropriate personal protective equipment.

- Inspect attachments regularly for signs of wear or damage.

- Never exceed the rated capacity of the attachment or the backhoe.

Can all backhoes accommodate these attachments?

- Most modern backhoes are designed to accept a variety of attachments, but it’s essential to check compatibility before purchasing or using any attachment.

Are there any maintenance tips for prolonging the life of attachments?

- Keep Backhoe Attachments clean and free of debris.

- Grease moving parts regularly.

- Inspect for wear and damage after each use.

- Store attachments in a dry, secure location when not in use.

How do I know which attachment is suitable for my specific tasks?

- Consider the type of work you’ll be doing and the materials you’ll be handling.

- Consult with equipment dealers or manufacturers for expert advice on selecting the right attachments for your needs.

Are there any financing options available for purchasing Backhoe Attachments ?

- Many equipment dealers offer financing options or lease programs for purchasing Backhoe Attachments, making them more accessible to businesses of all sizes.