Introduction

Backhoe vs. Excavator When it comes to heavy construction equipment, selecting the right tool can make all the difference in the efficiency and success of a project. Two commonly used machines in the construction industry are backhoes and excavators. Understanding their differences, strengths, and weaknesses is crucial in making an informed decision for your construction needs.

Understanding Backhoes

What is an Backhoes ?

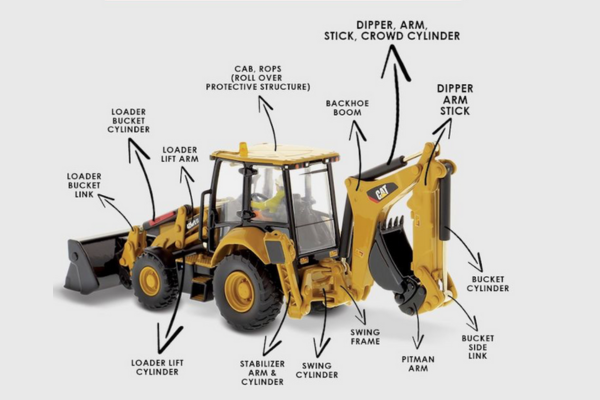

A backhoe is a versatile piece of equipment that combines the functions of a loader and an excavator. It features a digging bucket on the back end and a loader bucket on the front. This dual functionality allows backhoes to perform various tasks, including digging, lifting, loading, and backfilling.

Features and capabilities

Backhoes are known for their compact size, making them suitable for navigating tight spaces on construction sites. They offer excellent maneuverability and are often used for tasks such as trenching, excavating foundations, and loading trucks. With their hydraulic systems, backhoes can dig trenches with precision and efficiency.

Understanding Excavators

What is an excavator?

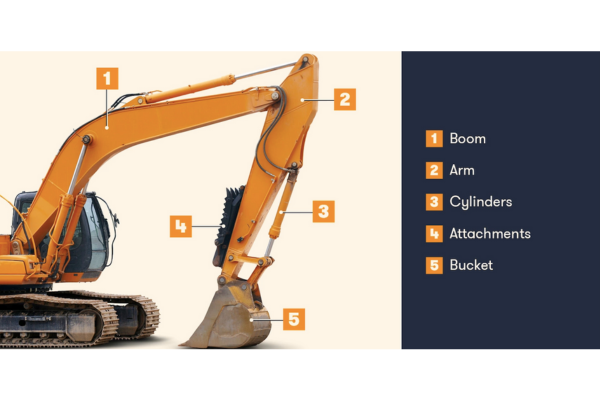

An excavator is a heavy-duty machine designed primarily for digging and earthmoving tasks. It consists of a boom, stick, and bucket, which can be equipped with various attachments for different purposes. Excavators are typically larger and more powerful than backhoes, offering greater digging depth and reach.

Features and capabilities

Excavators are renowned for their digging capabilities, making them ideal for projects that require deep excavations or extensive earthmoving. They can handle a wide range of tasks, including digging trenches, demolishing structures, clearing debris, and lifting heavy objects. Excavators are equipped with hydraulic systems that provide precise control and efficient operation.

Comparison of Backhoes vs Excavators

When choosing between a backhoe and an excavator for your construction needs, several factors must be considered.

Purpose and typical uses

- Backhoes are versatile machines suitable for a variety of tasks, including digging, lifting, and loading.

- Excavators excel in digging and earthmoving tasks, such as excavating foundations, digging trenches, and clearing land.

Performance in various tasks

- Backhoes are well-suited for smaller projects and tasks that require precision digging and maneuvering.

- Excavators are more powerful and can handle larger-scale projects, offering greater digging depth and reach.

Mobility and maneuverability

- Backhoes are compact and agile, making them easy to maneuver in tight spaces and on congested construction sites.

- Excavators are larger and may have limited maneuverability in confined areas, requiring more space to operate effectively.

Digging depth and reach

- Backhoes have a limited digging depth and reach compared to excavators, making them less suitable for deep excavations or long-reach tasks.

- Excavators offer superior digging depth and reach, allowing them to tackle larger and more challenging projects with ease.

Factors to Consider When Choosing Between Backhoes vs Excavators

Several factors should be taken into account when deciding between a backhoe and an excavator for your construction project.

Job requirements and scope

- Assess the specific tasks and requirements of the project to determine which machine is better suited to handle them effectively.

Budget considerations

- Consider the initial purchase price, as well as ongoing maintenance and operating costs, to ensure that the chosen machine fits within your budget constraints.

Terrain and working conditions

- Evaluate the terrain and working conditions of the construction site to determine which machine offers the best performance and maneuverability.

Versatility and multifunctionality

- Determine whether the project requires a machine that can perform multiple functions, such as digging, lifting, and loading, or if a specialized machine would be more appropriate.

Case Studies: Real-world Examples

To illustrate the differences between backhoes and excavators, let’s consider a few real-world examples of construction projects and the machines used.

Maintenance and Operating Costs

- Backhoes generally have lower maintenance and operating costs compared to excavators due to their smaller size and simpler design.

- Excavators may require more frequent maintenance and higher fuel consumption, especially for larger models used in heavy-duty applications.

Environmental Impact

- Both backhoes and excavators have environmental impacts, including emissions, noise pollution, and habitat disturbance.

- Proper maintenance and operating practices can help minimize these impacts and ensure sustainable construction practices.

Conclusion

Choosing between a backhoe and an excavator depends on various factors, including the scope of the project, budget considerations, and specific job requirements. By carefully evaluating these factors and understanding the capabilities of each machine, construction professionals can make informed decisions that maximize efficiency and productivity on the job site.

FAQs

Which is better for digging trenches: a backhoe or an excavator?

Both backhoes and excavators are commonly used for digging trenches, but the choice between them depends on the specific requirements of the job.

Backhoe: Backhoes are versatile machines that combine a loader at the front and an excavator arm at the rear. They are well-suited for tasks that involve digging relatively shallow trenches or working in confined spaces. Backhoes are often preferred for smaller construction projects or urban areas where maneuverability is crucial. They are also easier to transport between job sites compared to larger excavators.

Excavator: Excavators are heavy-duty machines designed specifically for digging and lifting tasks. They come in various sizes and configurations, with larger models offering more power and digging depth. Excavators are typically used for larger-scale projects that require digging deeper trenches or dealing with tougher terrain. They offer greater reach and digging force compared to backhoes, making them suitable for more demanding excavation work.

Can excavators be used for loading materials like backhoes?

Yes, excavators can be used for loading materials, although they are not as efficient for this task as backhoes. While backhoes are specifically designed with a loader at the front for efficient loading of materials, excavators primarily excel at digging and lifting tasks with their hydraulic arms. However, excavators can still be used for loading tasks by attaching a bucket or other loading attachments to their arms. This allows them to scoop up and move materials, although their range of motion and efficiency may not be as optimal as with a dedicated loader like a backhoe.

What factors should I consider when choosing between a backhoe and an excavator?

When choosing between a backhoe and an excavator, several factors should be considered:

Job Requirements: Assess the specific tasks you need the equipment for. If your primary need is digging shallow trenches or working in confined spaces, a backhoe might be more suitable. For deeper trenches or heavier digging tasks, an excavator could be the better option.

Maneuverability: Consider the maneuverability requirements of your job site. Backhoes are often more agile and easier to maneuver in tight spaces, making them ideal for urban environments or smaller construction projects. Excavators, while powerful, may require more space to operate efficiently.

Reach and Depth: Evaluate the depth and reach required for your digging tasks. Excavators typically offer greater reach and digging depth compared to backhoes, which can be beneficial for larger-scale projects or when dealing with challenging terrain.

Loading Capability: Determine whether you need the equipment to perform loading tasks as well. While backhoes are designed with loaders at the front for efficient loading of materials, excavators can be equipped with loading attachments but may not be as efficient for this purpose.

Transportation and Storage: Consider the logistics of transporting and storing the equipment. Backhoes are often easier to transport between job sites due to their smaller size, while larger excavators may require specialized transportation and storage arrangements.

Cost: Compare the purchase or rental costs of both backhoes and excavators, taking into account your budget and the overall value provided by each option.

Operator Skill Level: Assess the skill level of the operators who will be using the equipment. While both backhoes and excavators require training and expertise to operate safely and efficiently, some operators may have more experience with one type of equipment over the other.

Are backhoes more cost-effective than excavators?

Backhoes generally have lower upfront costs and are versatile for various tasks, making them cost-effective for smaller projects or tasks needing frequent function switching. Excavators, with higher operating costs, excel in heavy-duty digging and are more efficient for larger-scale projects or tasks requiring deep excavation. The choice depends on factors like project size, duration, and specific requirements

How can I minimize the environmental impact of using heavy construction equipment?

To minimize the environmental impact of heavy construction equipment:

- Use newer, fuel-efficient models or electric/hybrid options.

- Keep equipment well-maintained to reduce emissions.

- Train operators to use equipment efficiently and avoid unnecessary idling.

- Consider alternative fuels like biodiesel or natural gas.

- Use noise-reducing measures and control dust to minimize pollution.

- Recycle materials and properly dispose of waste.

- Plan construction to protect natural habitats and minimize disturbance.

- Monitor emissions and environmental impacts regularly.

- Consider green certification for projects to ensure eco-friendly practices.